Leading Providers of Unit Dose Technology, Unit Dose Labels, Strip Packaging, Bingo Cards, UD Automation, Unit Dose Supplies, Unit Dose Programs, Unit Dose Software

ARxIUM delivers best-in-class technology and unparalleled expertise focused on helping pharmacies of all sizes and types improve safety, productivity and efficiency. We provide comprehensive and scalable pharmacy solutions for every segment of the pharmacy market – health systems, long-term care, retail, and central fill – designed with category-leading automation hardware and workflow software, and supported by unmatched industry knowledge.

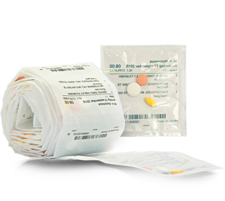

The FastPak™ line of packaging solutions is designed to provide scalable options for virtually any facility that has a need for packaging unit dose and/or multi-dose orders.

FastPak™ Elite:

The newest innovation in solid oral medication pouch packaging from ARxIUM for retail, long-term care and hospital pharmacies. This premium packager offers unparalleled versatility and modular configuration providing limitless formulary capabilities. Featuring 100% smart canisters, which can be placed anywhere in the device, the FastPak Elite enables you to automate up to 100% of your oral solid medications.

FastPak™ Verify:

A pouch verification solution designed to work with FastPak automated packaging systems. This new tool improves the efficiency of the pharmacy by automating the verification process of packaged oral solids by analyzing the quantity, shape and color of every pill in a package to ensure it matches the expected prescription for a given patient.

FastPak™ TableTop

Your primary unit dose packaging system, a complementary addition to another unit dose system, or a readily available backup solution. The horizontal operation virtually eliminates pill crushing and gel cap melting that is common with competing vertical-feed systems. The small footprint allows the systems to be placed in any location with no remodeling or disruption. The ability to add barcodes enables pharmacies to implement bedside barcode verification for medication administration.

The VMI INDIVION is VMI Care’s answer to the demands commonly seen in the pharmacy industry. Whether you run a Central Fill Pharmacy, a larger retail or hospital pharmacy, everywhere we see the same challenges: more items to pack, more services to deliver, stricter quality measures to satisfy, better data protection and stricter regulations. For the increasing number of high volume automated dose packaging hubs, a much higher level of efficiency is needed.

To cover these demands, many pharmacies have already automated their packaging process. However, the current pouch packaging machines are based on decades old technical principles, are not designed for really continuous and high volume production, hardly meet the increasing quality demands and result still in considerable unavoidable manual correction efforts, after automatic inspection.

The VMI engineers took up the challenge which resulted in the VMI INDIVION packaging system.

How does it work?

The VMI INDIVION produces daily dose pouch packs and can be seen as the heart of VMI’s high volume range of automated packaging solutions. The machine has an unrivaled capacity, producing up to 10,000 pouches per hour. The VMI INDIVION has an average dispensing accuracy better than 99.97% which is about 3 times more accurate than common pouch packaging machines in the market, while at the same time minimizing the risks of cross-contamination.

VMI has chosen a proven industrial robot for all canister handling in the VMI INDIVION which builds on VMI’s experience with other VMI machines in other markets. In the last few decades, robot technology has matured to very high levels of reliability and durability. VMI, as an innovative developer of process automation solutions, partners with all leading robot technology suppliers and is able to select the best, based on our experience, over many decades.

Canisters are stored and positioned on both the table and in the doors. The robot puts the smart canisters on the correct docking stations for release. Below the table are 72 specially designed hoppers, collecting medication for each single pouch. The most commonly seen reason for process assembly errors is tablets that bounce into the wrong pouch, or they are damaged. To avoid all this, the maximum dropping height in the VMI INDIVION has been reduced to only 21 cm (8 inch).

The VMI INDIVION is easy, accessible and can easily be operated by one single operator.

Single-dose, unit-dose, multi-dose, urgent orders, unexpected changes, produce to order, with the VMI INDIVION in combination with VMI PHARYS software, it all becomes an easy job.

Product highlights

VMI Care page: https://www.vmi-group.com/section/care/vmi-care-pharma/

VMI INDIVION: https://www.vmi-group.com/specifications/indivion/

VMI Pharys: https://www.vmi-group.com/specifications/pharys/

For more information, please contact John Ohradzansky at (330) 974-6527 or email johradzansky@vmi-group.com.

• View the VMI Care Platinum Pages Publication Ad

ScriptPro’s MP 100 and MP 400 are proven and reliable single- and multi-dose medication pouch packaging systems that fill pouches from 100 to 400 medication packaging cassettes plus auxiliary input trays that your staff prepares through an integrated control system. You can efficiently swap in additional cassettes as needed.

The system generates up to 54 pouches per minute (3,240 pouches per hour) with easy to read dosing instructions on each pouch. MP 100 and MP 400 incorporate barcode technology to ensure accuracy, and facilitate inventory replenishment with minimal downtime through intuitive, user-friendly software.

The pouch packaging systems integrate with ScriptPro’s workflow and pharmacy management software as well as non-ScriptPro systems.

MP 100 Medication Pouch Packaging System - https://assets-global.website-files.com/5e9726a182e4d42d25469d39/602ec30e96d85d12c0fb6af3_MP_100_updates_202102018.pdf

MP 400 Medication Pouch Packaging System - https://assets-global.website-files.com/5e9726a182e4d42d25469d39/602ec320c3c40be80680cf88_MP%20400_update_20210218.pdf

• Visit the ScriptPro Automation & Robotics Website

• Play the ScriptPro Automation & Robotics Informational Video

• View the ScriptPro Automation & Robotics Platinum Pages Publication Ad

• View the ScriptPro Automation & Robotics 20Ways Publication Profile

• Print the ScriptPro Automation & Robotics Booth Information

Pharmacy Automation Supplies (PAS) is your answer. Whether you’re an independent pharmacy supplying a local home with 30 day cold-seal cards, a retail store interested in supplying your patients a choice in the packaging they receive their prescription in, a high volume specialty LTC pharmacy using multi-dose cards, or a repackager using high volume heat seal cards with automation PAS has a solution. As a manufacturer our run & hold business model provides long run discounts and same day releases while our direct to end user sales channel eliminates brokers, middlemen, and wholesalers allowing you to get the most competitive pricing in the market.

For pharmacies who want to increase their visibility and branding, PAS has an in-house art department to assist with adding logos/colors to long runs of blister cards. If you prefer the convenience and flexibility of ordering a case at a time on your schedule, PAS carries stock blisters & cards in our warehouse available for release within one business day at our industry leading long run pricing.

PAS’s blister card program supports our goal of being a cost saving solution for ALL the consumables used in pharmacy. In addition to blister cards our 20 flexographic presses make us one of the industry’s largest manufacturers of Direct Thermal, Thermal Transfer, Laser, Piggyback, Reorder pull tab, Specialty, IV, and many more labels used in all pharmacy environments. PAS also manufactures paper bags and is a wholesale distributor of authentic Lexmark toners, thermal transfer ribbons, pharmacy vials, plastic bags, and more. Our mission has always been to help pharmacies save time, and increase profits, efficiency, and productivity and we deliver on that goal daily by helping our customers consolidate vendors without ever sacrificing price or quality.

As one of the industry leaders Pharmacy Automation Supplies recognizes that the products we manufacture are relied on to perform every day in the demanding world of pharmacy. Our reputation for quality, and responsiveness to the changing needs of our customers & in the industry, are just two of the reasons PAS has grown over the past 100 years from a small printing company to one of the most counted on suppliers in the industry.

Contact one of our support specialists today to learn how our unit dose, multi-dose, and consumable solutions can support your operations AND help save you money in an increasingly competitive marketplace!

• Visit the Pharmacy Automation Supplies Website

• View the Pharmacy Automation Supplies Platinum Pages Publication Ad

• View the Pharmacy Automation Supplies 20Ways Publication Profile

Unit Dose

Easily enhance your small volume medication packaging routine with the unmatched selection of liquid and solid unit dose products from Health Care Logistics. Find a variety of kits and accessories along with labels and printers to satisfy all your packaging needs in one spot at HCL!

Liquid Unit Dose Packaging

Shop HCL’s extensive inventory of liquid unit dose packaging products to find unit dose vials & caps, oral dispensers, labels, seals and tamper evident tapes and caps to meet all your liquid unit dose packaging requirements.

To visit HCL online click the link below, or call to speak to a member of our Customer Service team from 8:00 am to 8:00 pm EST Monday through Friday

• Visit the Health Care Logistics Website

• View the Health Care Logistics Platinum Pages Publication Ad

Noritsu understands the challenges you face with large, ever-changing formularies, shrinking reimbursements, and maintaining skilled labor. We recognize that there is no one-size-fits-all solution. That's why we tailor our solutions to meet the unique needs of each pharmacy. By working closely with you and your team, we create integrated packaging systems designed to achieve your specific business goals.

Noritsu’s LittleBot Series is a new line of compact, scalable blister card packagers.

Designed to fit into any pharmacy, the LittleBots bring ease of use, accuracy, and efficiency to your packaging workflow. Whether your employees are new or experienced, the LittleBots help them maintain consistent productivity and accuracy.

The LittleBots line consists of three innovative robots:

The Impact Series machines are built for high-production LTC pharmacies or retail pharmacies that have established LTC services.

Our accurate, fast, and reliable NX Series packagers feature a unique design engineered around efficient pharmacy workflow. The space-saving vertical drawer design allows for more medications in a smaller space, with easy refilling and stock rotation, while the patented "Intelligent Feeder" system ensures the highest level of accuracy.

You don’t need to be an engineer to appreciate the build quality of this equipment. Once you see, hear, and feel how smoothly the NX Series operates, you’ll be confident in its reliability. Reliable equipment means you can spend more time building your business.

The NV series of verification systems offer state-of-the-art medication validation through patient-regimented pouch and dose analysis. Built with durability and accuracy in mind, an NV system can dramatically increase your packaging throughput by quickly checking every pouch for accuracy.

At the heart of all our systems lies the NexusRx pharmacy control software suite. Combining pharmacy management, packaging, verification, and archiving into one efficient and versatile workflow, Noritsu NexusRx software lets you take control of your entire backroom operation. Whether it's having complete control over your orders prior to packaging, printing labels, or analyzing your packaging data, NexusRx provides the tools to manage and improve your day-to-day pharmacy operations while offering your customers more options and versatility.

Pharmacy Advantages

Facility Advantages

• Visit the Noritsu Pharmacy Automation Website

• View the Noritsu Pharmacy Automation Platinum Pages Publication Ad

• View the Noritsu Pharmacy Automation 20Ways Publication Profile

For more than 40 years, Euclid® Medical Products has been a trusted partner for hospital/retail pharmacies, long-term care facilities and third-party repackagers seeking high-quality, efficient multi/unit dose packaging and barcoding systems.

Euclid® Medical Products is excited to announce the introduction of two new next-generation multi/unit dose strip pouch adherence packaging machines called Axial®.

These next-generation packaging machines are built on a new revolutionary rotary design which allow for a very small footprint (The 144 Canister Machine has a 2’x2’ footprint and the 352 canister machine has a 2’x4’ footprint).

These machines can unit or multi-dose medications and can package at speeds up to 65 packages per minute. Storing up to 15 canisters of one medication for high volume runners, the machines can continue to package as canisters are being refilled.

The new rotary design allows for easy access to the canisters, as well as easy cleaning and maintenance. These machines also have RFID smart canisters and a built-in dehumidifier.

Features:

-2 Models: (144/352 canisters)

-Small footprint: 144 (2'x2') and 352 (2'x4')

-Speeds up to 65 packages per minute

-Can package and replenish canisters at same time

-RFID “Smart Canisters”

-Built-in dehumidifier

-Packaging materials contain technology that provides Fast Easy Opening

-Provides 300 DPI thermal transfer printing and can produce linear and 2D barcodes

Euclid® Medical Products is proud to offer a comprehensive line of oral solid/liquid unit-dose packaging machines (also known as strip packaging machines).

Products Include:

There’s a reason Euclid® Medical Products packaging systems are the most widely used machines in most pharmacies and contract re-packagers. It’s called “The Euclid® Difference”.

• Visit the Euclid Medical Products Website

• View the Euclid Medical Products Platinum Pages Publication Ad

• View the Euclid Medical Products 20Ways Publication Profile

Family-owned mfr of RX LABELS, PILL CARDS, CUSTOM BAGS & RX VIALS, plus the VIVID-1 PILL COUNTER, celebrating 45 years in 2024.

PILL CARDS – Choose from Heat Seal or Cold Seal single dose and multi-dose adherence packaging. We offer an extensive selection to help you service your customers, including MedTime color coded cards, Control Cards and Pill Cards for Robotic filling stations. Visit our website to view an extensive Long Term Care catalog highlighting the many varieties that are available, including DOSIS & SynMed packaging.

UNIT DOSE – Reclaimable Unit Dose packaging is available using special Unit Dose Pill Cards, or Medication Boxes. The Class B Unit Dose package includes perforated foil and 32 ct blisters in various sizes. Each dose has specific drug information printed on the back side of the foil including NDC, Lot #, Expiration Date and Manufacturer. Unit Dose packaging is also ideal for e-kits.

SEALING EQUIPMENT – Three levels of Heat Seal presses are available including 2-up or 4-up Manual Presses, 2-up Auto Open press, or our AutoSealer, which is the fastest sealer on the market – 3 second seal time. The AutoSealer doesn’t put off any heat, can seal ½” or ¾” depth pill cards without any conversion process, and has a lifespan of 15+ years.

BULK PRE-PACK EQUIPMENT - Pre-packing is the best way to reduce labor if you serve over 500 residents. We offer two levels of automation to meet your needs based on your volume. AutoFiller is best for 500-2,000 residents and can fill/seal up to 280 cards per hour, when paired with the AutoSealer. Our inline AutoTrans Conveyor has a max throughput of 600 filled, sealed and pre-pack labeled cards per hour, and is ideal for pharmacies servicing 2,000+ residents. Check out our online videos for more information.

MAX PAK – Max Pak is a high capacity companion to your pill card system, and is used to store bulk quantities of oral solids in medication carts. It can be used for Floor Stock or “dispensed” OTCs, or High Volume Rx that require multiple pill cards for a 30-day supply. It is not used for repackaging.

Since 1979 Rx Systems has been a part of the community of independent pharmacy, now with locations in five states, and occupying over 250,000 sq ft of manufacturing and warehouse space. Our company was created with the intent of providing a one-stop shop for pharmacy supplies. An emphasis on customer service, while providing quality products at a fair price, has created long term relationships with our customers.

• Visit the Rx Systems Website

Accu-Chart® has been in the unit dose drug distribution and barcode systems business for over 40 years. Today, we offer a variety of solutions for hospital and pharmacy needs such as unit dose packaging, barcode labeling, blister card filling, medical and surgical supplies and much more.

To learn more, click the link below to visit our website or call (847) 252-7300 to speak to a sales representative today. We look forward to speaking with you!

• Play the Accuchart Informational Video

Medical Packaging Inc., LLC (MPI), a global healthcare packaging solutions provider for 50 years, provides innovative pharmacy packaging solutions for packaging oral solid and oral liquid medication, and overwrapping and labeling of ampoules, vials and syringes, which contribute to saving patient’s lives by reducing medication errors while also increasing efficiency and automation in pharmacy packaging operations.

MPI’s pharmacy packaging solutions, which include the packaging system, MPI-certified consumable materials and MPI’s exclusive Pak-EDGE™ UD Barcode Labeling Software, have been developed in adherence to industry specifications and meet the requirements of governing regulatory bodies for the repackaging of medication into unit dose. Optional integration to First DataBank drug data, imprints and images library, assists the pharmacy in reducing potential dispensing errors and increasing safety and efficiency.

MPI’s solutions for packaging oral solid medication include the Auto-Print® Standard packaging system, which packages sixty (60) packages per minute (ppm) and the Auto-Print® Express 90 packaging system, which packages ninety (90) packages per minute (ppm). Additional functionality can be achieved through the optional Oral Solid Feeder attachment, which packages bulk medication from the bottle into individual unit dose packages, the Variable Length Option, which allows for adjustment to the package length to accommodate packaging of non-standard sized tablets or capsules, and the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

MPI’s solutions for packaging oral liquid medication include the Fluidose® Series 6 packaging system for packaging medication into unit dose cups and the Auto-Draw® Syringe Filling System for packaging medication into oral syringes.

The Fluidose® Series 6, which packages twenty-two (22) packages per minute (ppm), dependent upon fill rate and viscosity, produces a single, barcoded, unit dose package containing liquid medication to be delivered to the bedside. Fluidose® Series 6 is compliant with The Joint Commission (TJC) regulations for dispensing oral liquid medication and is capable of dispensing volumes between 1 mL and 40mL. Additional functionality can be achieved through the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

The Auto-Draw® Oral Syringe Filling System is a semi-automatic solution that is capable of filling most oral slip syringes up to 50 mL in volume of varying viscosities providing the solution for batch filling of syringes with speed, accuracy and repeatability. Filling operations can be completed in a manner of seconds and no additional software is required. MPI’s Auto-Draw® is ideally used for oral liquid medication doses 1 mL or greater or for those medications that are not typically packaged in unit dose cups or are not commercially available in unit dose.

MPI’s solutions for ancillary packaging include overwrapping and labeling solutions for ampoules, vials and syringes. MPI’s overwrapping solutions include the Pharmacy Accessory Bagging System (PABS), which produces up to thirty-five (35) filled and sealed packages per minute. Labeling and barcoding is done directly on the bag, eliminating costly labels and allowing for customization of the barcode. Bags are available in several different sizes to accommodate even the most irregularly sized items. MPI’s Auto-Print® Max Bagger, packages in bags with a punched hole in the upper half of the package specifically for use with centralized, robotic systems.

MPI’s labeling solutions include the Pharmacy Accessory Label Printer (PALP), which is offered with either direct thermal or thermal transfer technology to quickly and efficiently print accurate barcoded labels for placement on ampoules, vials and syringes. Labels are available in several different styles to accommodate all labeling needs. MPI’s Auto-Wrap® Syringe Labeling System, with labeling and wrapping speed of up to twenty (20) syringes per minute, automates the process of labeling syringes and assists in increasing production throughput while reducing repetitive stress injuries (RSI) by producing a printed label and automatically wrapping it around a syringe in one single motion. The Auto-Wrap® can accommodate any type of oral or injectable syringe from ½ mL to 60 mL without any need for adjustment or changing of parts. Open-faced design allows for easy loading of label stock and access to all controls.

• Visit the Medical Packaging Inc LLC Website

• View the Medical Packaging Inc LLC Platinum Pages Publication Ad

• View the Medical Packaging Inc LLC 20Ways Publication Profile

Parata

Pharmacies and patients benefit from pouch packaging technology...

Manchac Technologies

Boost pharmacy production and offer caregivers more convenience through hands-free robotic blister packaging...

Connect with thousands of pharmacy professionals throughout every practice setting.

The server is experiencing a problem at this time. Try again later.