Medical Packaging Inc., LLC (MPI), a global healthcare packaging solutions provider for 50 years, provides innovative pharmacy packaging solutions for packaging oral solid and oral liquid medication, and overwrapping and labeling of ampoules, vials and syringes, which contribute to saving patients lives by reducing medication errors while also increasing efficiency and automation in pharmacy packaging operations.

MPIs pharmacy packaging solutions, which include the packaging system, MPI-certified consumable materials and MPIs exclusive Pak-EDGE UD Barcode Labeling Software, have been developed in adherence to industry specifications and meet the requirements of governing regulatory bodies for the repackaging of medication into unit dose. Optional integration to First DataBank drug data, imprints and images library, assists the pharmacy in reducing potential dispensing errors and increasing safety and efficiency.

MPIs solutions for packaging oral solid medication include the Auto-Print® Standard packaging system, which packages sixty (60) packages per minute (ppm) and the Auto-Print® Express 90 packaging system, which packages ninety (90) packages per minute (ppm). Additional functionality can be achieved through the optional Oral Solid Feeder attachment, which packages bulk medication from the bottle into individual unit dose packages, the Variable Length Option, which allows for adjustment to the package length to accommodate packaging of non-standard sized tablets or capsules, and the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

MPIs solutions for packaging oral liquid medication include the Fluidose® Series 6 packaging system for packaging medication into unit dose cups and the Auto-Draw® Syringe Filling System for packaging medication into oral syringes.

The Fluidose® Series 6, which packages twenty-two (22) packages per minute (ppm), dependent upon fill rate and viscosity, produces a single, barcoded, unit dose package containing liquid medication to be delivered to the bedside. Fluidose® Series 6 is compliant with The Joint Commission (TJC) regulations for dispensing oral liquid medication and is capable of dispensing volumes between 1 mL and 40mL. Additional functionality can be achieved through the Barcode Verifier Option, which automatically scans each package to assure that the printed barcode can be accurately scanned at the bedside.

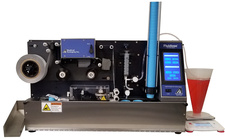

The Auto-Draw® Oral Syringe Filling System is a semi-automatic solution that is capable of filling most oral slip syringes up to 50 mL in volume of varying viscosities providing the solution for batch filling of syringes with speed, accuracy and repeatability. Filling operations can be completed in a manner of seconds and no additional software is required. MPIs Auto-Draw® is ideally used for oral liquid medication doses 1 mL or greater or for those medications that are not typically packaged in unit dose cups or are not commercially available in unit dose.

MPIs solutions for ancillary packaging include overwrapping and labeling solutions for ampoules, vials and syringes. MPIs overwrapping solutions include the Pharmacy Accessory Bagging System (PABS), which produces up to thirty-five (35) filled and sealed packages per minute. Labeling and barcoding is done directly on the bag, eliminating costly labels and allowing for customization of the barcode. Bags are available in several different sizes to accommodate even the most irregularly sized items. MPIs Auto-Print® Max Bagger, packages in bags with a punched hole in the upper half of the package specifically for use with centralized, robotic systems.

MPIs labeling solutions include the Pharmacy Accessory Label Printer (PALP), which is offered with either direct thermal or thermal transfer technology to quickly and efficiently print accurate barcoded labels for placement on ampoules, vials and syringes. Labels are available in several different styles to accommodate all labeling needs. MPIs Auto-Wrap® Syringe Labeling System, with labeling and wrapping speed of up to twenty (20) syringes per minute, automates the process of labeling syringes and assists in increasing production throughput while reducing repetitive stress injuries (RSI) by producing a printed label and automatically wrapping it around a syringe in one single motion. The Auto-Wrap® can accommodate any type of oral or injectable syringe from ½ mL to 60 mL without any need for adjustment or changing of parts. Open-faced design allows for easy loading of label stock and access to all controls.

Share booth #11393 with others.